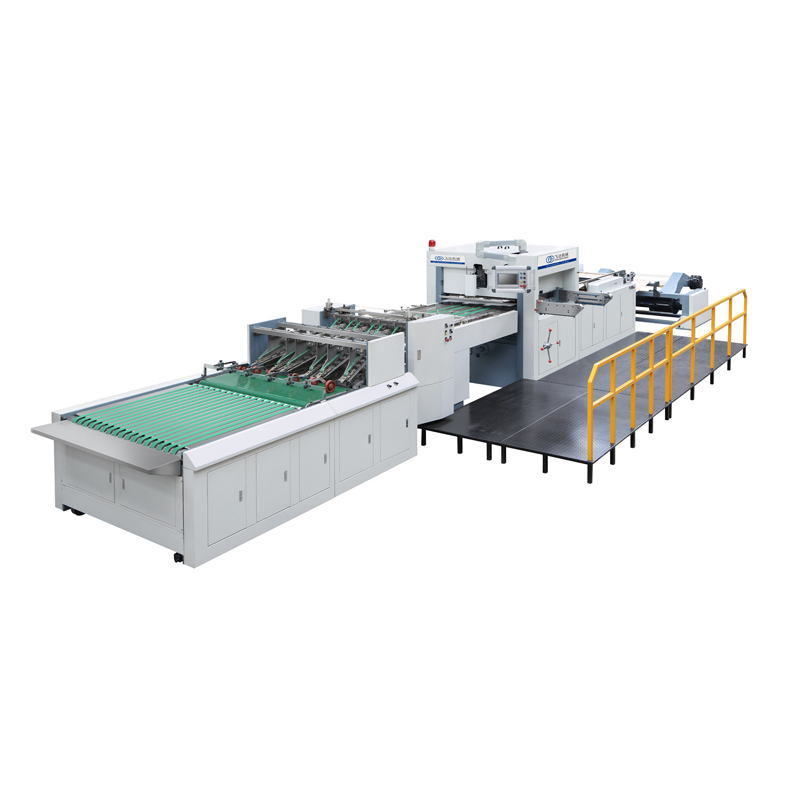

China Beat Automatic Paper Box Making Machine – ZX-1200 Automatic Carton Erecting Machine – FEIDA

China Beat Automatic Paper Box Making Machine – ZX-1200 Automatic Carton Erecting Machine – FEIDA Detail:

Product Video

Advantage

1.Servo motor control the forming mold (press mold) (advanced, more accurate than mechanism cam control)

2.Using full servo system (3 servos in machine replace cam system)

3.Easy exchange molds to make different products, charging and adjusting time is very short.

4.PLC program control the whole line, available to make complicated boxes.

5.Automatic collection, stock, and count.

6.Human being designed control button and panel, more easy and safe runs by user.

7.PLC could save the adjusted parameter after you finish adjustment, it will help you save time.

| Production speed | Max. 180 boxes/set |

| Glue Material | Water-base cold glue |

| Raw Material | 180-600gsm cardboard /coated paper/ corrugated paper |

| Paper thickness | Max 1.6mm |

| Air source | 2kgs/cm² |

| Dimension | 2950*1300*1300mm |

| Machine weight | 1800kg |

| Total power | 3kw |

| Sample |

Speed(The Speed varies depending on the box size) |

Ship box Ship box |

120-180 boxes/min

|

Burger box Burger box |

100-180 boxes/min |

Take away box Take away box |

60-110 boxes/min |

Square box with cover Square box with cover |

60-110 boxes/min |

Irregular triangle box |

30-50 boxes/min |

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for China Beat Automatic Paper Box Making Machine – ZX-1200 Automatic Carton Erecting Machine – FEIDA , The product will supply to all over the world, such as: Oslo, Kuwait, Lithuania, You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.

Write your message here and send it to us