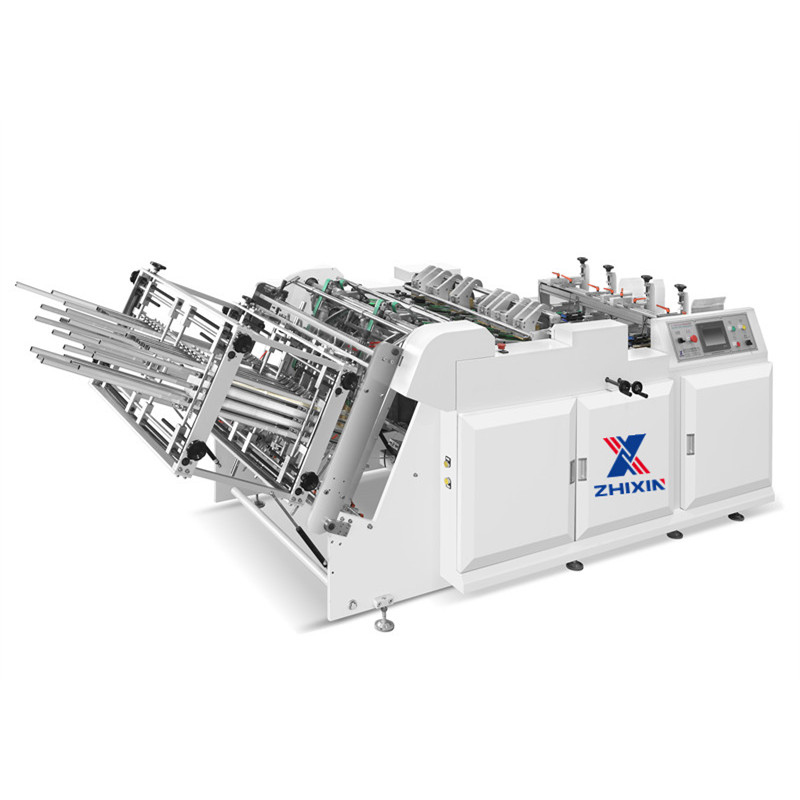

ZX-1600 Double Workshop Carton Erecting Machine

Product Video

Characteristic

1. Servo motor control the forming mold (press mold) (advanced, more accurate than mechanism cam control)

2. Using full servo system (3 servos in machine replace cam system)

3. Easy exchange molds to make different products, charging and adjusting time is very short.

4. PLC program control the whole line, available to make complicated boxes.

5. Automatic collection, stock, and count.

6. Human being designed control button and panel, more easy and safe runs by user.

7. PLC could save the adjusted parameter after you finish adjustment, it will help you save time.

Technical Parameters

| model: | ZX-1600 | |

| Production speed speed: | 100-320pcs/min | |

| Material: | 200-620gsmCorrugating paper thick: 1.6mm | |

| box size: | Length: | L100-450mm |

| Degree: 5°-45° | ||

| Width: | B100-600mm | |

| Height: | H 15-200mm | |

| Power: | 6kw | |

| Air requirement: | 0.5Mpa, 0.4cube/min | |

| Voltage: | 380V 50Hz | |

| Power Power: | 4.5kw.h | |

| Size: | 3600*1850*1700mm | |

| Weight: | 2800kgs | |

Configuration

|

Servo |

Schneider |

|

Air cylinder |

AirTAC |

|

Linear guideway |

Taiwan Hiwin |

| Core bearing |

Japan NSK |

|

PLC |

Schneider |

|

Screen |

Schneider |

|

Servo driver |

Schneider |

|

Photoelectricity |

Omron |

|

Relay |

Schneider |

|

Switch power supply |

Schneider |

Sample

Burger box Burger box |

160-240 boxes/min |

Ship box Ship box |

200-260 boxes/min |

Hot dog box Hot dog box |

200-260 boxes/min |

Pizza box Pizza box |

140-180 boxes/min |

Take away box Take away box |

140-180 boxes/min |

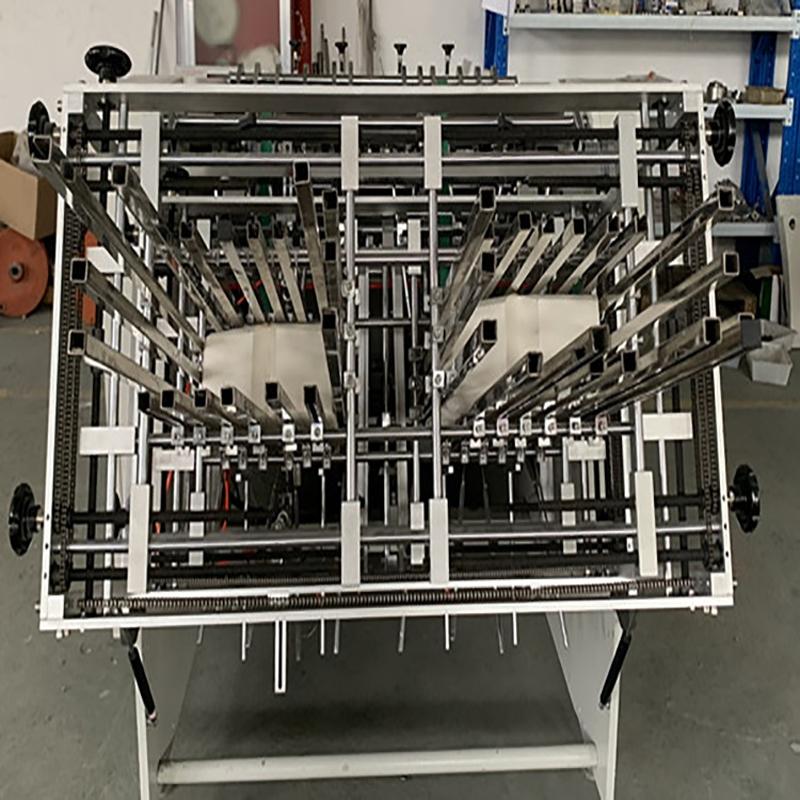

Machine Display